I had a client come in that wanted to make some custom rims for this vintage Indy car. They couldn’t find any good tires for the stock 16″ diameter rims and wanted to make a replica 15″ version so some quality rubber could be used and easily sourced.

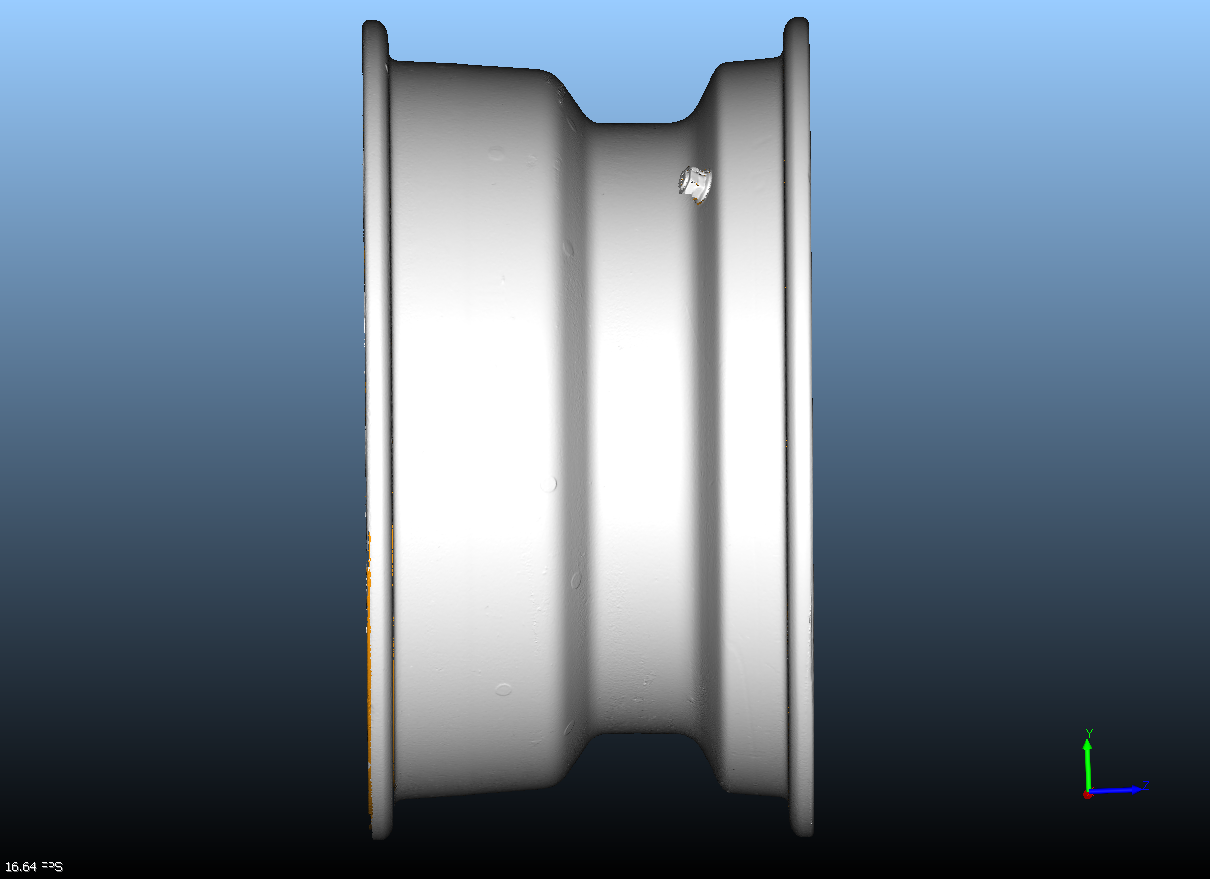

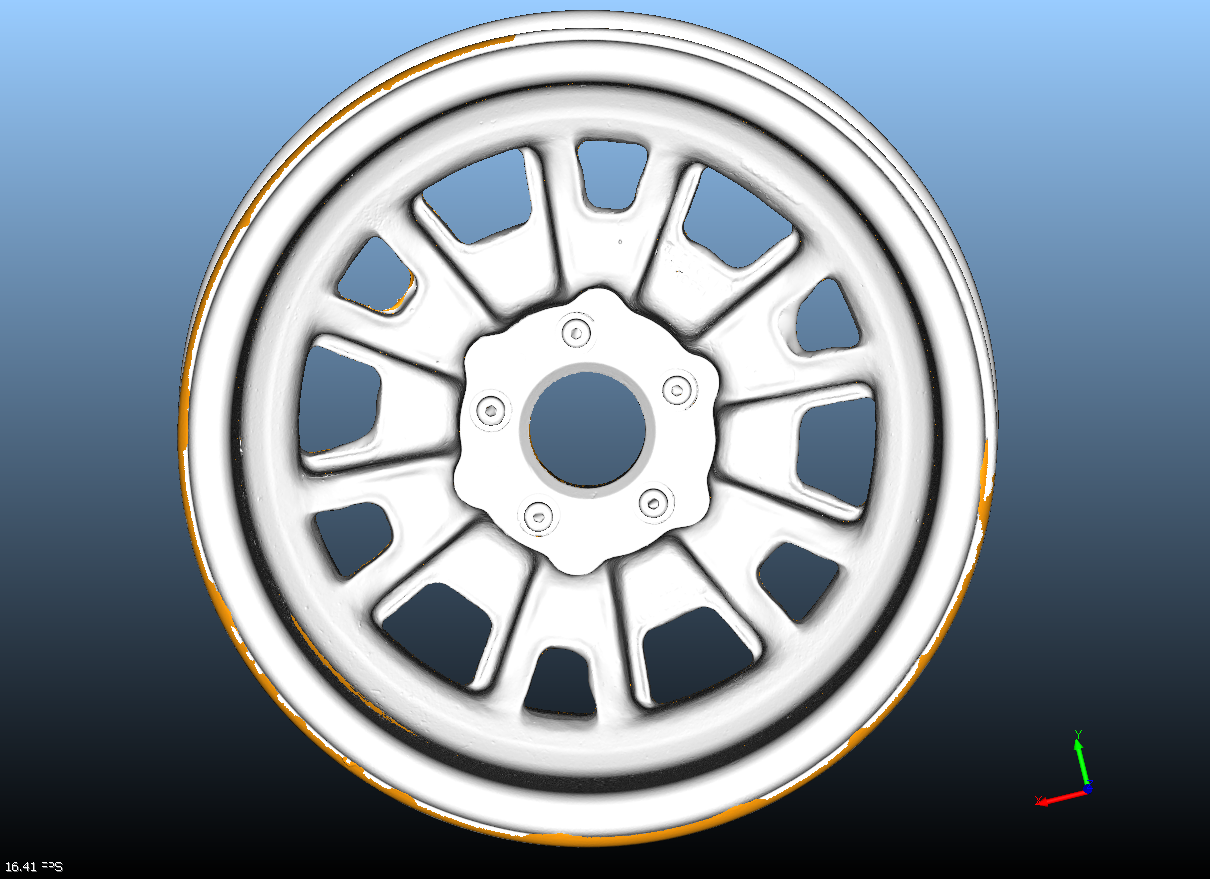

I 3D scanned the original magnesium rims using our Rexcan CS+ scanner. Then we started down the path of sizing and sourcing some two piece spun aluminum rims. These would need to accommodate the brake calipers and also be able to house a replica center billet.

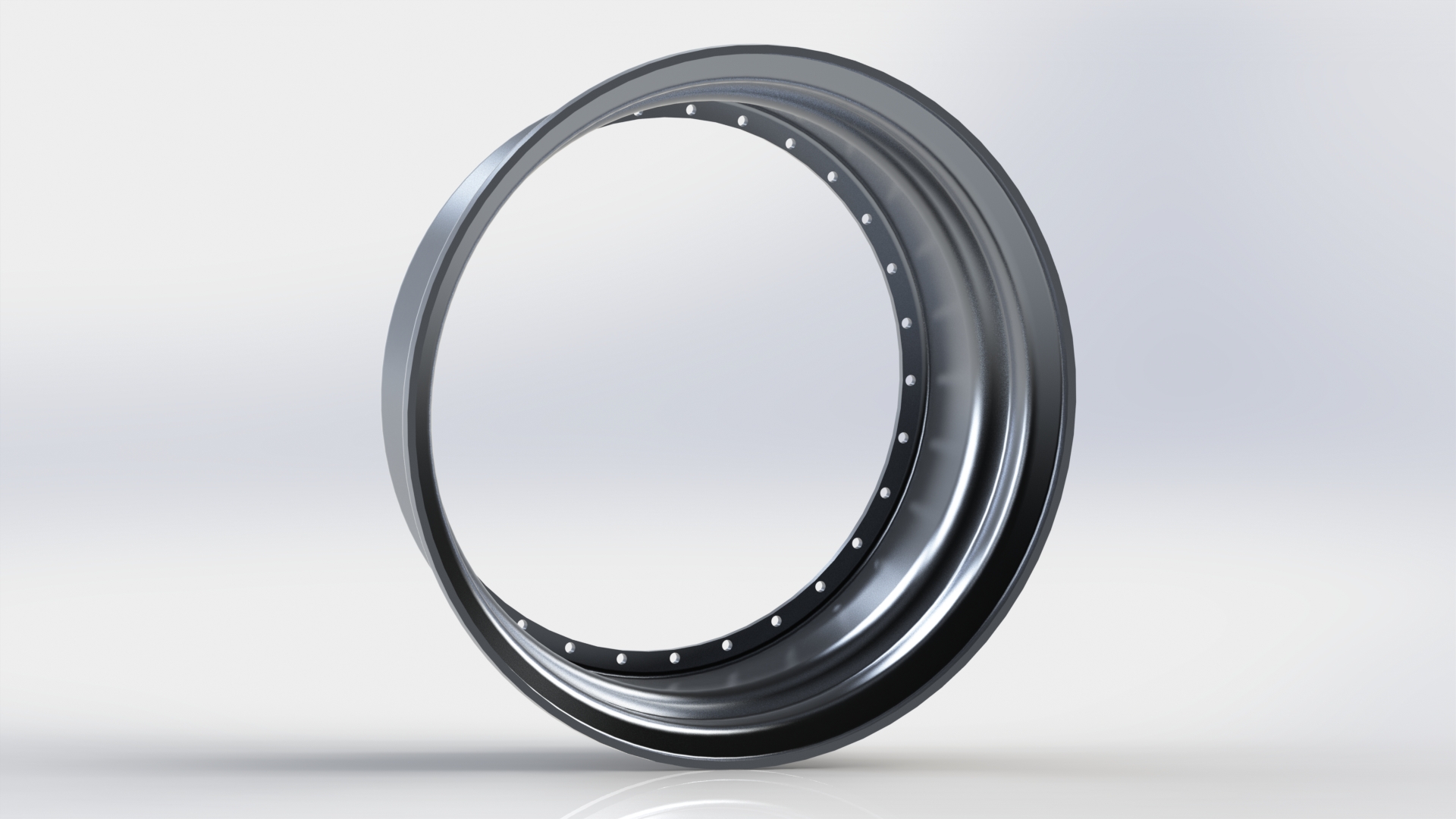

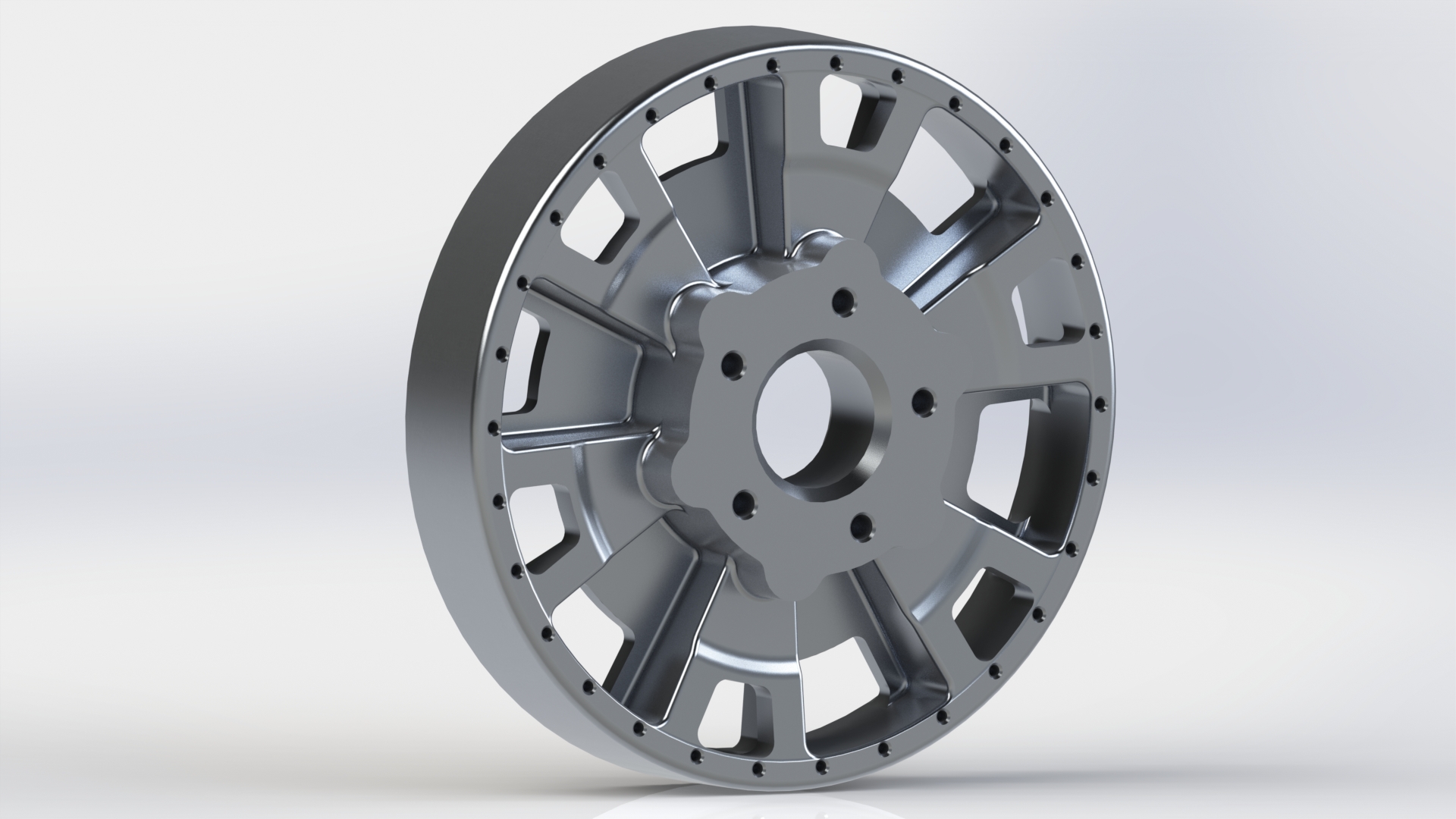

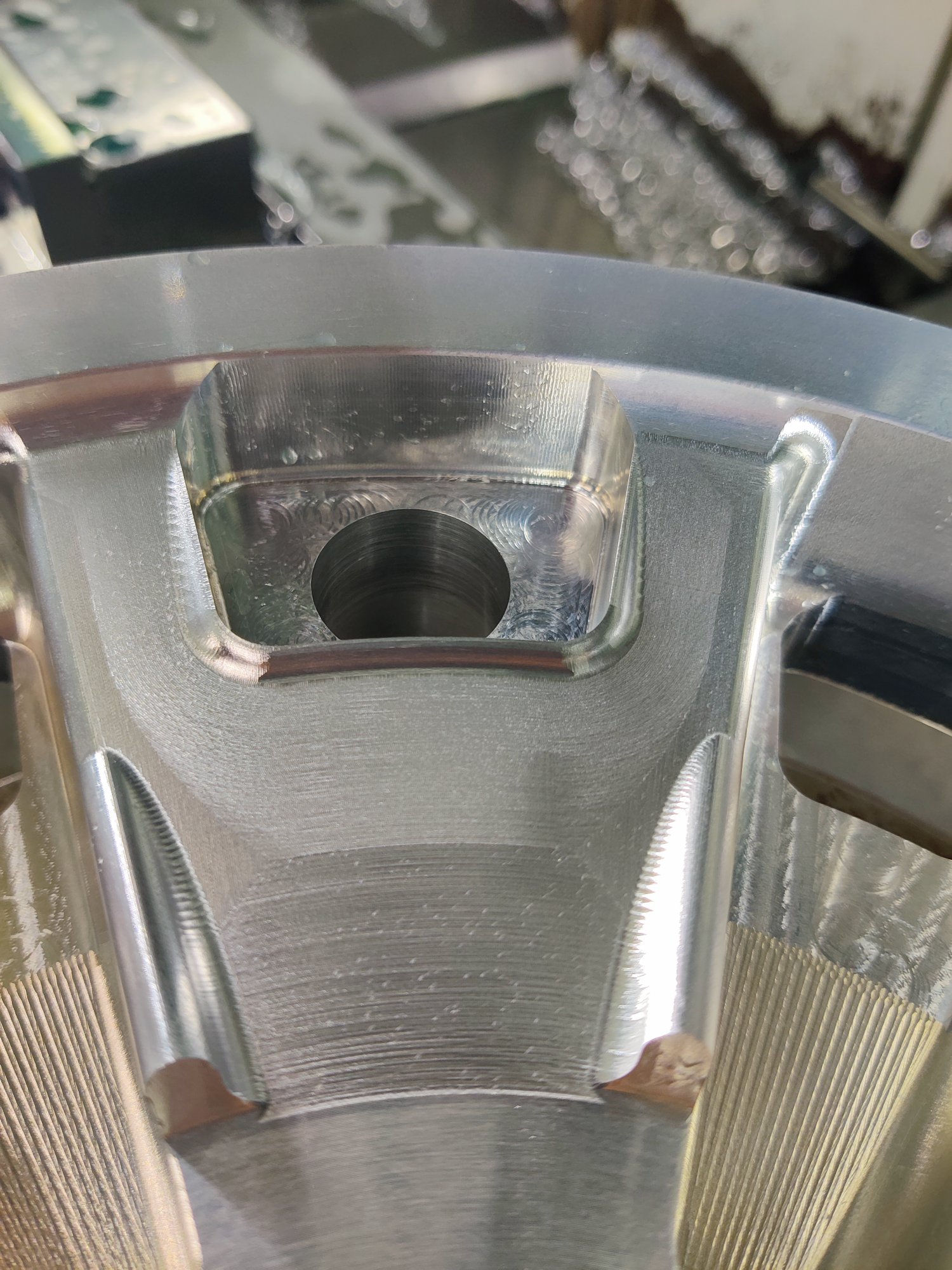

Here are some 3D models of what I came up with for the billet center. Also shown is the front half of the two piece rim assembly. The centers were machined from 6061 aluminum and are made a very close fit to the spun front. I was surprised how consistent the I.D of the spun rims were and they were relatively round. Within about .020″ t.i.r on the worst one.

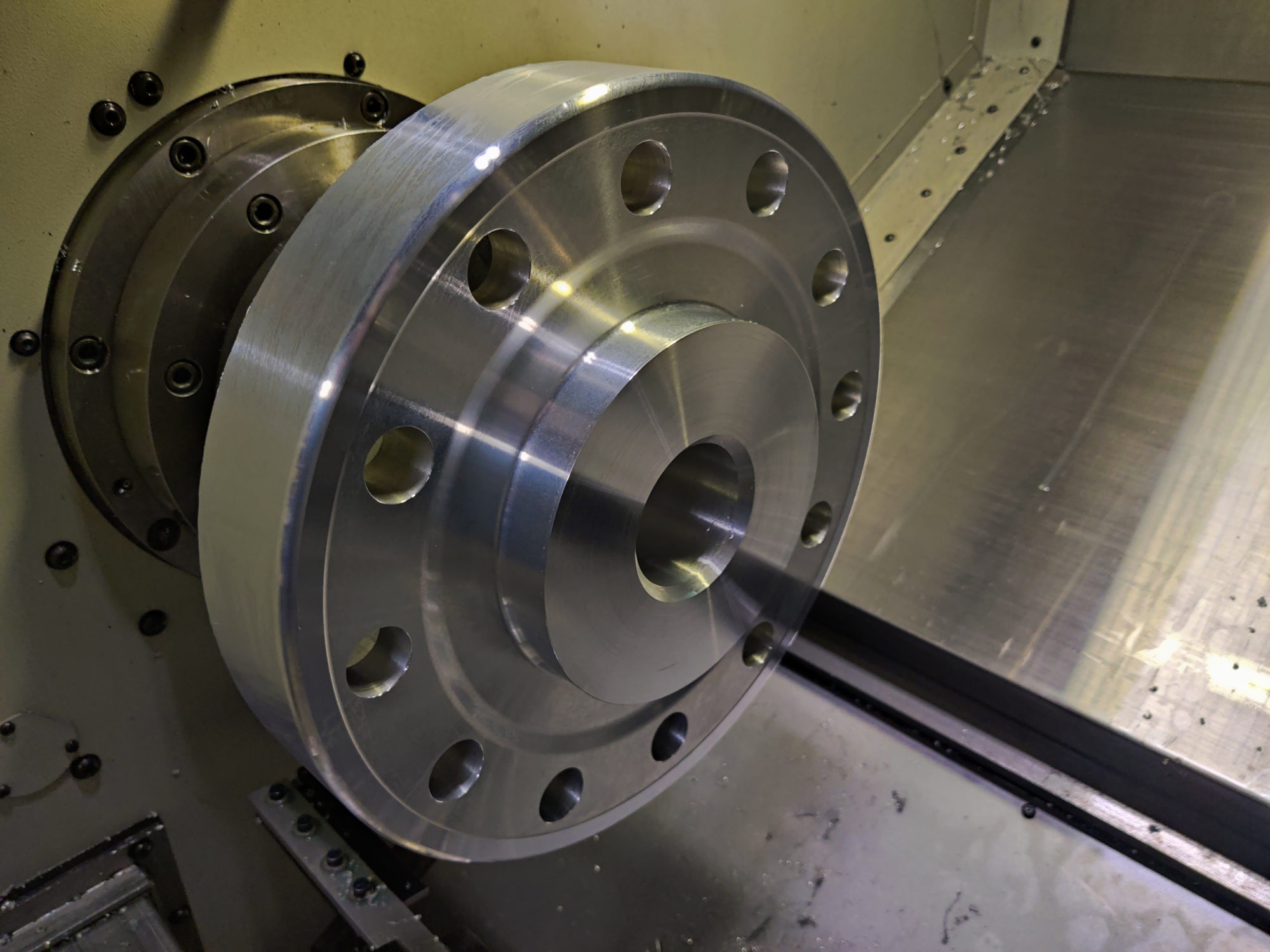

Then came the time to actually start cutting them out of the billets. I started off in the mill to rough some material out and also leave a boss to grab onto in the lathe chuck. The outside diameter, inside bore/chamfer, front face and the rear features were all finished in the lathe. Then back into the mill to rough and finish all the cutouts and holes.

Pretty much done.. These have been anodized and tires mounted.

Super happy with the finished product!

Comments are closed.